Other Blogs

-

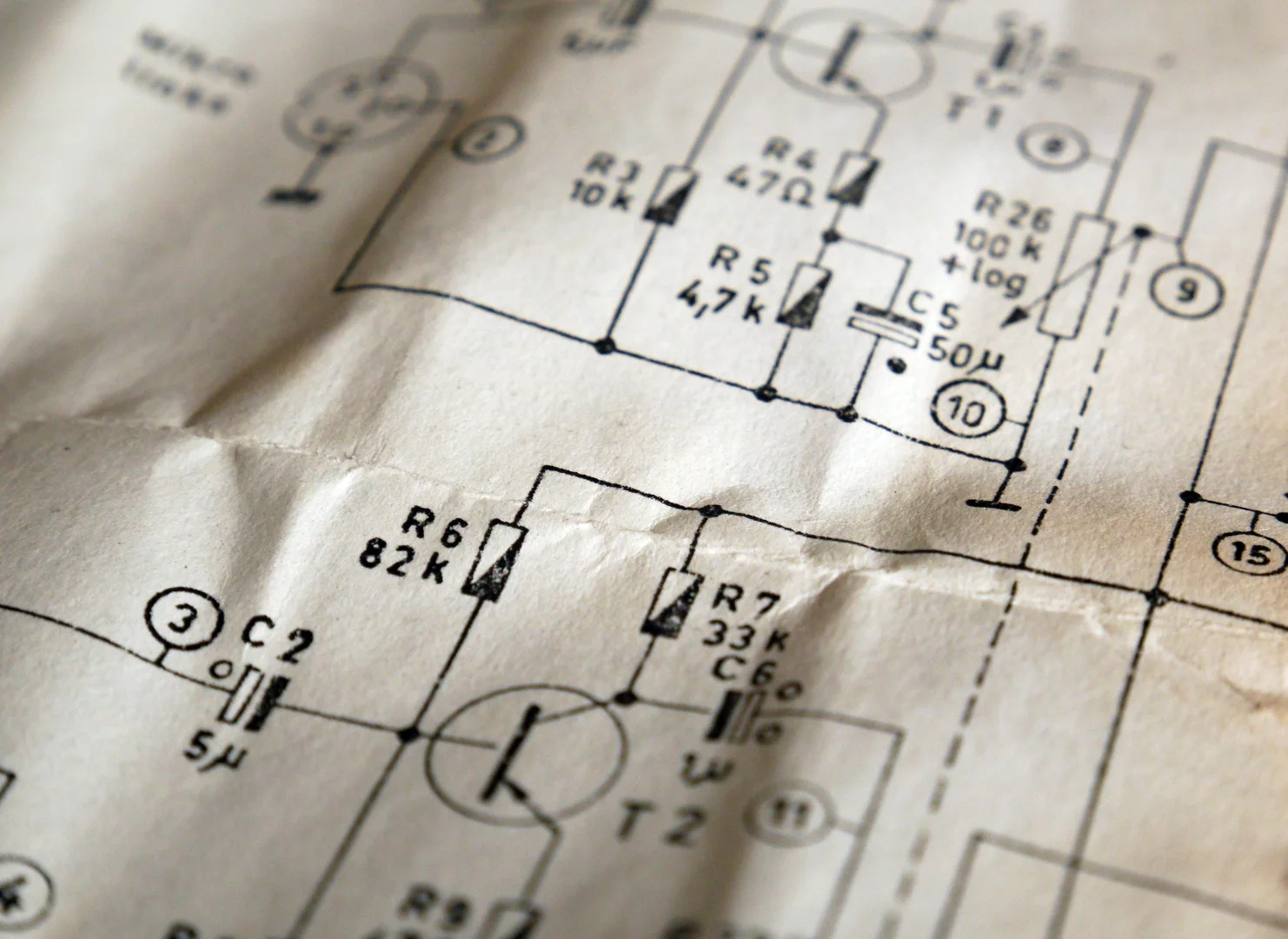

Why Do Transformers Make Noise and How Can It Be Reduced?

Transformers can sometimes produce a noticeable hum or vibration noise when operating. This is often a natural process, but under certain conditions, it can become an unwanted source of noise.

-

Dual Voltage Transformers

Dual voltage transformers allow to serve regions with different voltage requirements without the need for separate transformers.

-

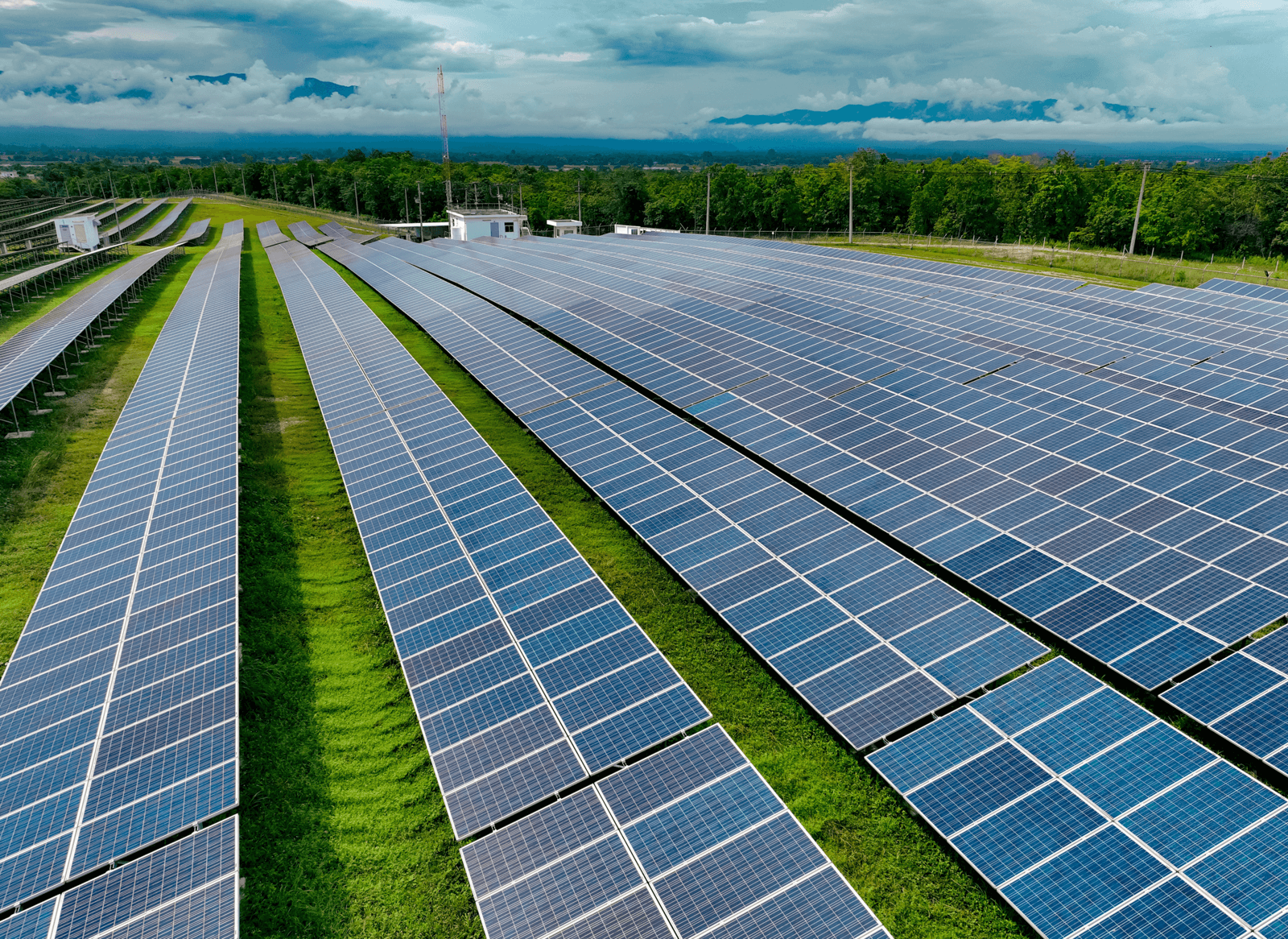

The Role of Solar Farms in the Transition to Carbon-Free Energy

Carbon emissions caused by fossil fuels are cited as one of the biggest causes of global warming and climate change. Therefore, countries and companies looking for ways to reduce carbon emissions are turning to renewable energy.

-

Solar Farms: The Clean Energy Source of the Future

While the world's need for energy is increasing rapidly, the environmental impact of fossil fuels continues to pose a major threat.

-

Innovative Transformer Technologies that Minimize Energy Loss

Energy efficiency is becoming an increasingly high priority in today's energy sector.

-

Transformer Optimization for Sustainable Energy Resources

With the widespread use of renewable energy sources, transformers...

-

Transformer Oil Analysis: Detect Faults in Advance

One of the most important elements that ensure the healthy operation of transformers is...

-

Ways to Reduce Your Carbon Footprint in Power Grids

Today, the energy sector is undergoing a major transformation to reduce its carbon footprint.

-

The Most Durable Transformer Solutions for Industrial Use

Transformers used in the industrial sector are exposed to severe operating conditions and therefore durability is a major factor.

-

5 Effective Ways to Extend Transformer Life Cycle

Transformers are critical components of power grids and their long life ensures uninterrupted operation of the system...

-

The Role and Future of Transformers in Smart Grids

Energy grids are becoming smart with digitalization and IoT technologies. In this transformation, transformers...

-

Transformer Selection Guide for Efficient Energy Distribution

In energy distribution processes, choosing the right transformer is of great...

-

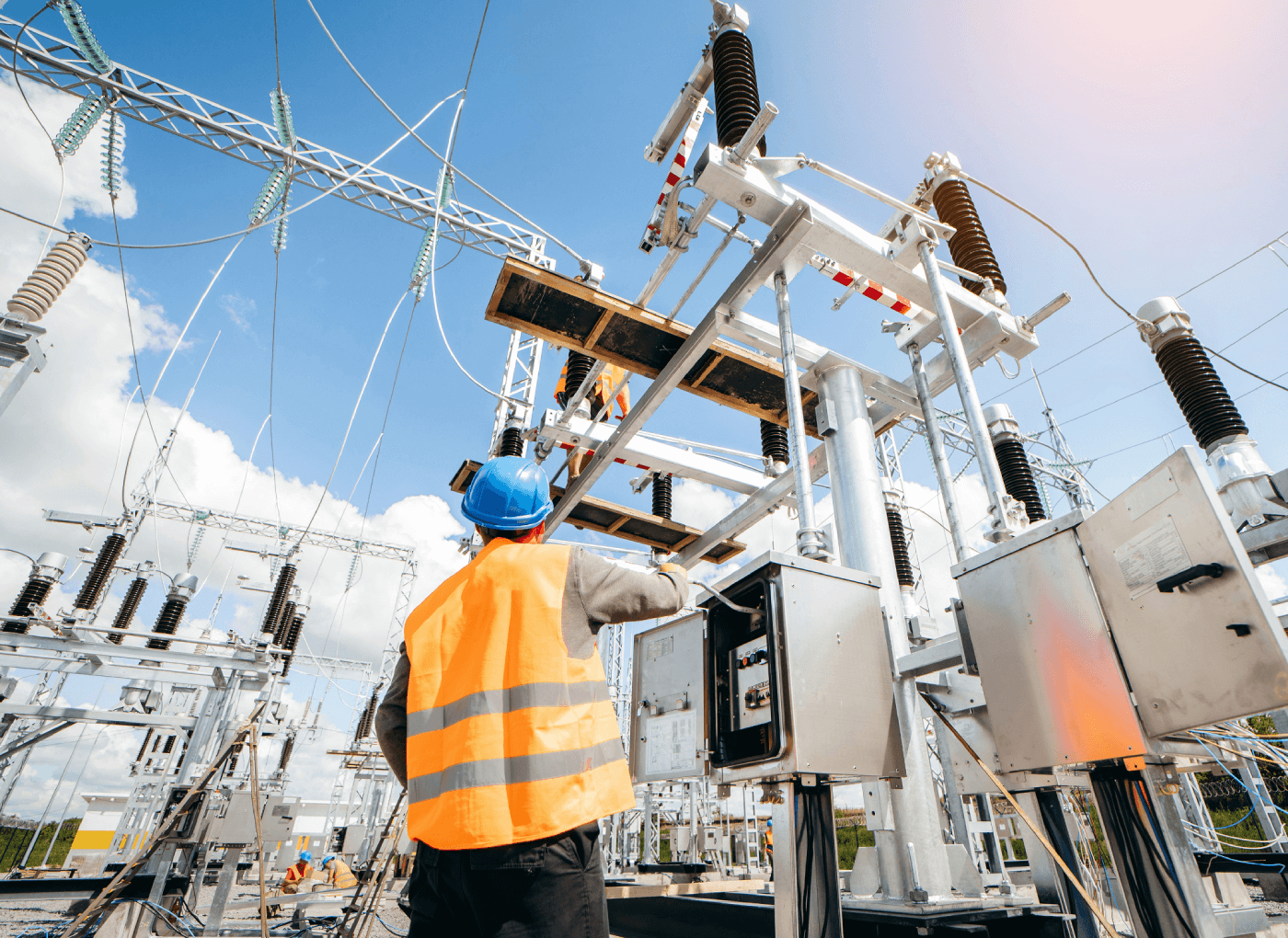

Transformers: Hidden Heroes of The Electric Energy World

Transformers, the heart of electric energy in the world, is with us in every aspect of life. However, a transformer, which distributes electric energy to our lives in a safe, efficient andsustainable way, often works like an unrecognized hero. With an impact ranging fromindustry to homes, transformers not only regulate the flow of electric energy, but also form the basis of economic, environmental and technological solutions.

-

Future Trends in Transformer Technologies and Sustainable Solutions

The energy sector is rapidly transforming in terms of sustainability and efficiency...

-

Energy and Art: Where Transformers Meet Creativity

Energy infrastructure is often valued for its functionality, with little attention given to its aesthetic potential.

-

Microgrids: The Future of Local Energy Solutions

The energy world is rapidly evolving from large, centralized grids to more localized and independent solutions.

-

Smart Transformers: The Future of Energy Management through Digital Transformation

In today’s energy sector, digitalization is not only transforming how businesses operate but also fundamentally reshaping energy management systems.